Essay: Forest Research and Development History

Introduction

There are numerous environmental concerns facing society today and most of them center on ways of maintaining an ecological balance in our world. It is clear that currently we need fuel to run cars; keep homes warm or cool; and keep the lights on in schools and other buildings. Coal, oil, natural gas, wood products and other natural resources are all used daily. How do we balance society's needs with those of the environment?

One tool is scientific research. Researchers examine new types of fuels for our cars, new ways to reuse items (recycling), new forms of energy, more efficient appliances, and the list could go on and on. There are also researchers seeking ways to improve our forests and make improved use of forest products. Throughout the last century and a half, making better use of forest products as a result of forest research has had a significant influence on addressing environmental concerns in society. Forest research is intended to accomplish numerous goals. Forest researchers work to collect, analyze and report on things that might harm our forestlands, such as insects and diseases. Forest products researchers work to improve technology for using timber and other forest resources more efficiently.

One organization that conducts forest research is the U.S. Forest Service. As part of the Forest Service, the Research & Development branch contributes to scientific discoveries and conservation of many natural resources in the U.S. There are also many universities and several private companies that conduct forest research in the U.S. and around the world.

Forest research contains several focus areas. Some researchers focus on product safety and human health. Urban forest researchers might analyze the effects of an urban forest on air quality and water quality in the city. Other research focuses on the economics of forestlands. These researchers might examine the economic impacts of changes in laws that govern use of the forests. Others focus their research on various ecological issues in forests such as fire, plant genetics, insects, and forest diseases. Research is also conducted on watersheds, landscape management, soils, and wilderness.

Then there are those researchers that focus on forest products. These researchers are attempting to find new technologies to improve wood products and reduce waste when harvesting and processing trees. For example, a forests product researcher may come up with new ways to create paper using recycled materials.

Image 1: August 1957: General view of Kawishiwi Ranger District Laboratory personnel checking spruce branches for spruce budworm masses. Image from U.S. Forest Service, Eastern Region Historical Photograph Collection |

Image 2: August 1957: Research Entomologist collecting samples in spruce budworm biological study area. Jim Bean Kawishiwi Ranger District. Image from U.S. Forest Service, Eastern Region Historical Photograph Collection |

In 1909 the Secretary of Agriculture, James Wilson, announced the University of Wisconsin in Madison as the future site of the Forest Products Laboratory . The Forest Products Laboratory opened on April 1, 1910 and its primary goal was to discover new technologies for producing wood products while creating less logging waste. Developing more efficient ways of producing wood products meant more products from fewer trees.

Examples of Research Accomplishments

Gum Naval Stores:

One example of the contributions of forest research in the Southeast comes from the Lake City Research Center in Lake City , Florida , where new techniques for naval stores production were developed. Naval stores refers to products extracted from raw pine gum from living pine trees. These products included: turpentine, rosin, and pine oils. These materials were used in building and maintaining wooden boats. They were used on sailing ships to caulk seams and to protect ropes. No ship left port without them. These pine products are still referred to as “naval stores,” but they now have many different uses. Now they are used to manufacture inks, adhesives, perfumes, and hundreds of other products.

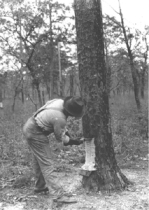

Image 1: March 1928, Chipping a streak on a face. A streak was usually chipped once a week from March to November. Usually 1/4-inch to 5/8-inch of wood is removed up the tree and 1/2-inch to 3/4-inch deep. A series of these streaks chipped one above the other is called a face. The face shown is the result of nearly one season's chipping. This man is putting the first streak on the second year's face. |

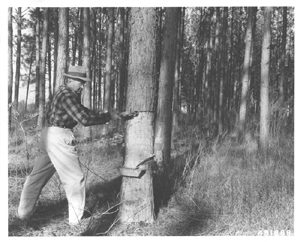

Image 2: March 1928, Choctawhatchee National Forest, Florida. A typical view in a turpentine woods, showing trees which are being worked for the fifth year. |

In 1925, naval stores gum production was an inefficient process that destroyed millions of small trees each year before they reached logging size. In order to extract the gum or resin from a tree, a deep cut was made each week in the tree. This wound to the tree, called chipping, would cause gum (sap) to flow. The gum was collected in an iron gutter system. The gum naval stores industry needed to collect a greater amount of gum through an easier method. And, at the same time they wanted to keep the trees growing. If the trees could be grown to a larger size, then many more products could be made from the same trees.

Florida |

|

|

Image 3: Naval Stores, 1950s. Improved gum naval stores extraction methods required new tools and techniques. Special tools were required for removing bark and applying acid-treatment. These pictures depict new tools and the application of sulfuric acid to increase gum production and reduce tree damage. |

|

Due to research, naval stores practices drastically changed over several decades. The Lake City Research Center found that nearly half of the chipping labor could be saved with no loss in gum production by spraying sulfuric acid on a fresh cut to prolong the flow of gum. This one research development saved the naval stores industry about a million dollars in 1951 when applied to about one-fourth of the producing trees. The Lake City Research Center also developed a new type of chipping tool which removed only a strip of bark, and left the tree usable for other resources, such as pulp and other wood products. Austin Cary, a logging engineer, and Eloise Gerry, the first female scientist to work at the Forest Products Lab in 1910, are two people often cited for their research contributions to the new chipping techniques and better production methods for the gum naval stores industry. Using a lighter bark hack for chipping spiral gutters for collecting the resin and bringing it to the collection basin, and double-headed nails were some of the new methods and equipment developed for extracting gum and all helped in creating more effective naval stores production.

Watershed Research:

One of the main reasons for establishing forest reserves, later to be National Forests, in the U.S. was for the protection and improvement of water supplies. The importance of forests in flood protection was recognized by foresters very early on. Between 1905 -1907 President Theodore Roosevelt declared over 150 million acres of forest reserves, mainly in the West. Research on the waters in National Forests was a priority almost from the beginning of the USDA Forest Service in 1905.

One of the first watershed studies in the U.S. was the Wagon Wheel Gap Project in Colorado , which began in 1909 and ended in 1926. This was a cooperative project with the U.S. Weather Bureau and the Forest Service. This project studied of the effects of timber removal on water yield (or stream flow) and erosion under the conditions of the central Rocky Mountains . The lead scientist of Wagon Wheel Gap was Carlos Bates . The Wagon Wheel Gap research plan was to observe weather patterns and stream-flow for two neighboring watersheds in the Rocky Mountains for several years. After make initial observations on both watersheds, the forestland in one of the watersheds was harvested for timber. Then a comparison was made for the amount of stream-flow and amount of erosion in the stream before and after removal of the forestland. The other watershed was used as a control. [ In a controlled experiment, two nearly identical tests are conducted. In one of them the factor being tested (in this case forest harvesting) is applied. In the other, the control , the factor being tested is not applied.] The Wagon Wheel Gap study found that forest harvesting, at first, increased annual water yield compared to the control watershed, however, the water yield increase became smaller as new trees and vegetation began to grow back. It was determined that it took about seven years for the forest to recover from harvesting. The Wagon Wheel Gap study set several standards for future research projects. In future research projects personnel would live on site, new instruments were used in the studies, and researchers studied soils, geology, and vegetation of the watersheds, as well stream-flow and erosion. Over the last century hundreds of forest watersheds have been monitored and used in watershed studies.

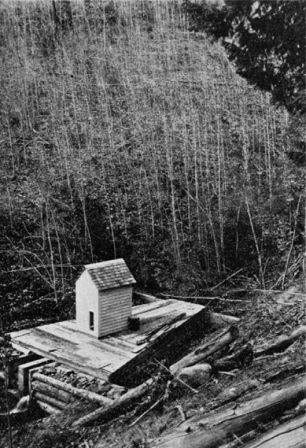

Image 6: The evaluation station at the Wagon Wheel Gap Project in Colorado. This was the model for later small forest watershed studies in the U.S. with a control watershed and an observation period prior to treatment. Photo from the USDA Weather Bureau (1928).

Forests offer significant opportunities for improvement in water quality through proper management. Much of the watershed research conducted in the national forests was intended to increase water yields from forest watersheds in times of severe drought, and as urban areas grew and needed more water. Research was also conducted to examine the quality of water provided by the nation's forested watersheds, as well as the effects of timber harvesting and roads on erosion and water quality.

A surge of environmental regulations in the 1960s and 70s re-energized an interest in watershed research and forests. Suddenly, water and the people who studied it were gaining federal funding to conduct research. Geologists, hydrologists and soil experts, among other scientists, were soon being hired to conduct watershed research to evaluate the effectiveness of forest management practices in protecting water quality. Researchers began to develop management practices to limit effects of timber harvesting and road construction. The value of watersheds in the U.S. became more apparent and research to preserve those watersheds increased. Since 1970, over 2000 articles have been published on watershed research. It is these watershed studies that continue to be used to evaluate forest management plans and alternatives, as well as regulate watershed uses. In the contiguous 48 States, about 18 percent of the nation's water supply originates on forests managed by the USDA Forest Service. As forest management practices change, there will continue to be questions about the effects on water quality and quantity.

Recycled Paper:

In Europe and the U.S. through the mid-1800s all paper could have been considered recycled paper. Old rags and worn-out clothing were the primary source of fiber used in mills for paper production, because the process for making paper from wood had not yet been developed. As the demand for paper grew, it became harder and harder to find enough old rags for use as fiber to make enough paper to meet this demand. The first machine for grinding wood to pulp for paper production was patented in 1844 . However, it wasn't until the late 1860s that Americans first began making paper from wood. In the late 1800s paper was mass-produced and created a more affordable product. Cheaper paper, schoolbooks, fiction, non-fiction, and newspapers became more readily available to all the members of society by 1900. As people began to use more and more paper and create additional waste the idea of recycling old paper began to slowly develop. Early recycled fiber was mostly used to produce products of lower quality, such as newspaper.

The U.S. Forest Products Laboratory made significant advances in recycling paper in the late 1960s and again in the 1990s. Recycling helps extend the functional life of wood fiber and helps reduce the buildup of waste in landfills. Initially, recycling paper was usually more expensive than producing new paper from wood, and therefore, at first, paper plants had little economic incentive to create recycled goods and consumers had little incentive to buy the more expensive products. In 1967 the Forest Products Lab built a Pulp and Paper Pilot Plant to conduct research on paper recycling techniques. In 1993, the Forest Products Lab built a new pulp laboratory and remodeled the existing paper testing laboratory to further paper production studies.

Image 6: In 1970, Gary Anderson (right) entered a contest for college students to create a recycling symbol and he won.

Paper recovery for recycling has increased significantly since the mid-1980s. Research has been conducted by numerous private companies across the U.S. Recycling research also resulted from a public demand for reducing landfill waste and timber harvesting beginning in the 1960s and really taking hold around the time of the first Earth Day in 1970. The recycling symbol used today was created in that same year, 1970, by Gary Anderson, a student at the University of Southern California . While the public outcry for recycling varied at different periods over the past 30 plus years, it has had an impact on the paper industries need and desire to find new solutions for recycling.

In 1994 the Forest Products Lab combined efforts with the U.S. Postal Service, Springborn Testing & Research, paper recovery companies, paper recyclers, adhesive manufacturers, and chemical suppliers to conduct experiments on recycling paper, especially paper containing adhesives. Removal of pressure sensitive adhesives from recovered paper posed a major problem for the paper recycling industry. At the time the U.S. Postal Service purchased about 12% of these adhesive products and therefore initiated this recycling research project. Removing contaminants from recycled paper pulp is one of the biggest technical barriers to paper recycling. Contaminants are unwanted components that come from ink, plastic films, paper coatings, adhesives and various other sources. Companies across the U.S. offered samples of new adhesives and suggestions for new recycling methods. Research findings as a result of this combined effort have led to improved paper recycling techniques for all contaminated paper. Additional studies in the mid-1990s found that enzyme treatments given to used paper fibers resulted in improved bleach-ability (making paper white) and contaminant removal. Enzyme treatments are the addition of a complex protein to the initial recovered paper pulp, helping make contaminants easier to remove. This research developed a new process, which when followed by traditional bleaching processes, was one of the first steps to help improve the brightness of recycled paper.

In 2000, research at the University of Florida 's Engineering Research Center for Particle Science and Technology created a new process for recycling paper that lowered the cost to the producer. This research was conducted by Hassan El-Shall and Brij Moudgil and developed a new technique used to remove inks from used paper. The technique replaced one type of chemical, which was expensive, with a blend of a cheaper mix of chemicals. By lowering the cost of the recycling process the hope was that it would be more economical and enhance the recycling incentive for paper companies. While people in the U.S. wanted to use recycled paper, paper companies could not make a profit selling recycled paper. Therefore many companies were hesitant to produce large amounts of recycled paper. This new recycling technique would allow the benefits of recycling to include corporate profits, as well as protecting the environment and reducing energy use. A ton of paper from recycled pulp saves at least 14 trees, 3 cubic feet of landfill space and 7,000 gallons of water, according to the Environmental Protection Agency and other government sources.

Image 7: Recycling Logo of today is very similar to Anderson 's original image.

U.S. paper consumption is the highest in the world. In 2006, it was estimated that each person in the U.S. consumed roughly 730lbs of paper per year. That accounts for about one-third of the world's paper consumption, even though the U.S. has roughly 5% of the world's population. In 2006, about 53.4% (53.5 million tons) of paper used in the U.S. was recovered for recycling. Most paper is recycled into newsprint, tissue, boxboard, and chipboard. Recycled paper has several problems; low brightness, high contaminant levels, and low paper strength. Therefore only small amounts of it are used to create the paper products that are consumed most. Research is being conducted at the Forest Products Lab to develop new technologies needed for recycling materials into all types of paper, paperboard (cardboard), composites, and lumber. Hopefully in the future this research will yield a recyclable paper and other products of a higher quality that will be consumed most often, therefore reducing the wood resources necessary to make these products.

Conclusion

Forest products research is critical to the social and economic well being of people on a global level, because the demand for wood and paper continues to increase while the resource continues to decrease. As world population grows, the need for sustainable use of our natural resources will only continue to grow. Forest research will remain a necessity to identify and solve major forest resource issues and problems, while offering economic gains. Changes in gum production came out of a need for greater amounts of resin with less damage to potential timber harvests. Many watershed projects occurred due to a need for greater amounts of water from the same limited source or out of a need for cleaner water sources. Many paper recycling techniques came out of a need to reduce costs to paper companies and businesses using paper products. So while sustainability of forests is an added bonus, many times it is economic, political, or ecological needs that drive the research in the first place. As the focus on global climate change and environmental awareness increases and people in the U.S. and the world begin to demand more ecologically-friendly products, we can expect to see new discoveries due to forest research.